Burj Al Arab

Dubai, UAE

“

Inspired by the graceful form of a sailboat, the Burj Al Arab stands as an icon of luxury hospitality in the Middle East.

”

Key Data

Location

Dubai, UAE

Project Type

Leisure, Hospitality, Iconic

Client / Developer

Jumeirah Hotels and Resorts

Architect / Consultant

W.S. Atkins & Partners

Main Contractor

Al Habtoor Engineering Enterprises Co. L.L.C & Murray & Roberts (Concor)

Façade Area

85,000 sqm

Scope of Work

Design, supply, manufacture, and installation of 85,000 sqm of semi unitized curtain walling system:

-

35,000 sqm of External envelope, Mitsubishi Aluminium composite cladding panels retained on an extruded Aluminium grid framework.

-

50,000 SQM of pressure equalised high-performance semi-unitised curtain walling, designed to withstand wind pressures of up to 3.2 KPA

-

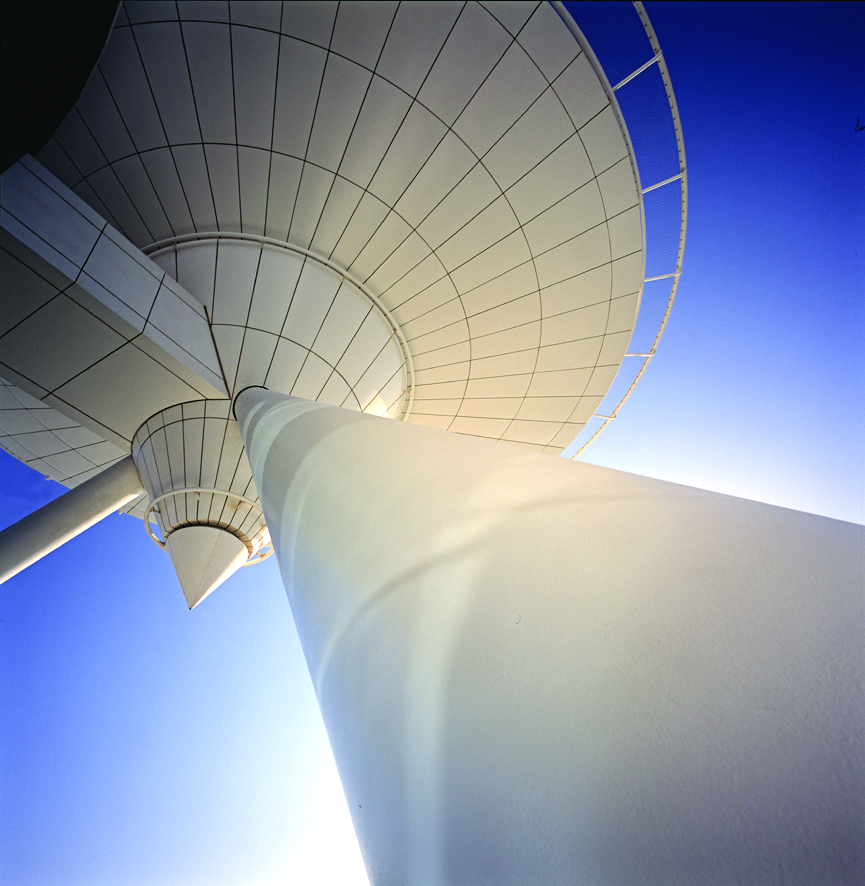

Cladding for helipad at the top level of the building suspended glazing assembly for the rooftop scenic restaurant

Levels

60

Project Height

321 Meters

Date of Award

1996

Date of Completion

1999

Overview

Inspired by the shape of a sailboat about to head into the Arabian Gulf, the triangular-shaped building’s design began with the intent to create a recognisable landmark for the emerging city. Upon completion, Burj Al Arab was the world’s tallest hotel and included the world’s tallest atrium which rises 182 meters through the interior of the building.

As the skyline of Dubai continues to expand Burj Al Arab will remain a key landmark that will not only be an essential part of Dubai’s world image, but it will also serve as a reminder of the transition era when Dubai emerged into the city it is today.

Insights

The main building façades are clad with a semi-unitized modular curtain walling system, with double glazed units in alternate storey height bands of light and dark blue, separated by white-coloured spandrel panels designed to break up the appearance of the large elevations.

To create a more comfortable and controllable internal environment, the glass is highly reflective and has a low thermal conductivity to reduce the solar and heat gain from the external desert climate.

The cladding to the main core and the exoskeleton legs and horizontals is composed of white powder-coated resin bonded aluminium panels. Such panels have the advantage over conventional aluminum or stainless steel panels in that they can be stiffened on the rear face to resist high local wind pressures on the tower, yet still appear flat and undistorted on the front face.